Jan 23, 2024

The pumpjacks dotting Alberta’s landscape might not look like an entry point to the booming electric vehicle (EV) industry. But Liz Lappin sees things differently. When the geologist joined the Energy Futures Lab as a Fellow in 2017, she brought a bold idea: to make Canada a globally competitive lithium provider.

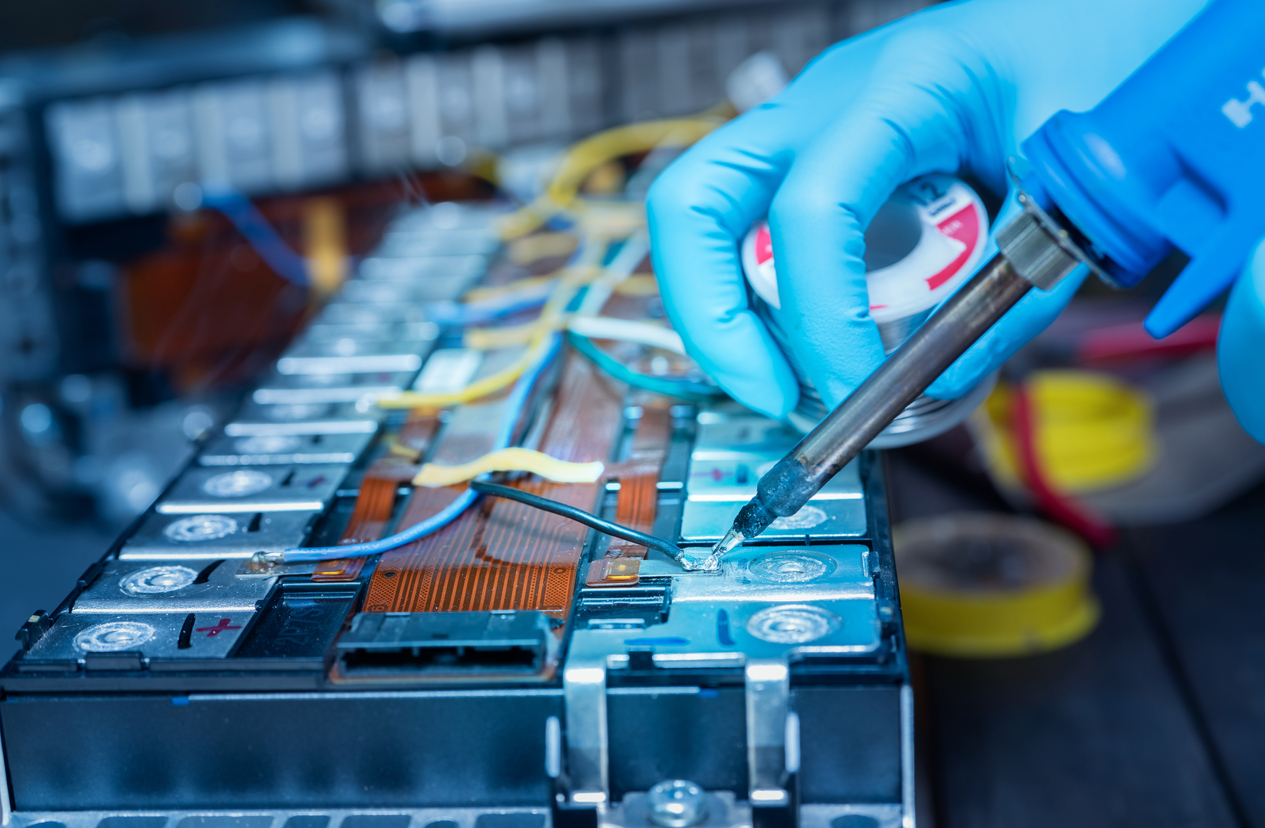

Lithium is a key ingredient in EV batteries. Currently, most of the world’s supply comes from either hard rock mining in Australia — a process with big environmental costs — or from salt lakes in South American countries with dubious human rights records.

But it’s also found in wastewater pumped from Alberta’s oil and gas wells, she explained, and new processing technology was being developed that could quickly separate it out. As a result, today’s waste product could play a valuable role in tomorrow’s energy system.

What started as a discussion of lithium quickly became much bigger. Canada also boasts significant reserves of many other critical battery ingredients — including nickel, cobalt, sulfur and graphite — providing an opportunity to create an extensive value chain.

The question was how to support the emergence of a new industry from the ground up.

“A lot of success, honestly, comes down to how you frame and position the work,” says Erin Romanchuk, Deputy Director at the Energy Futures Lab (EFL). Alison Cretney, EFL’s Managing Director agrees: “When you can help the system see itself as a system, you can spot opportunities, action them faster and create more impact,” she says.

EFL is a leader in bringing together diverse perspectives, encouraging participants to think beyond the status quo and co-creating solutions that work for everyone.

Working with EFL allowed Lappin to test ideas, iterate them and collaborate with staff and the community of Fellows. One of the results was the 2020 formation of the Battery Metals Association of Canada (BMAC): a trade organization that convenes key players from across the supply chain. BMAC then worked with EFL to establish a vision and national roadmap for the nascent industry.

The 2022 roadmap lays out strategic priorities, from catalyzing battery recycling markets to developing creative financial mechanisms to establishing public-private-Indigenous partnerships. A key pillar is bolstering Canada’s ability to process raw minerals domestically, instead of exporting them. And that’s where Western Canada’s deep experience in resource development could come into play.

Today, oil and gas is Canada’s number one export. Cars and automotive parts are number two. As global markets move away from internal combustion vehicles, both sectors are facing significant disruption, and the country needs new industries to fill the void. That’s where a robust battery metals supply chain could be transformative.

The key is making sure we do it right. “How do we create the conditions in the system where everyone can thrive — businesses and humans and the environment?” Romanchuk asks.

To help answer that question, BMAC is developing a Western Battery Hub and turning to ELF for strategic support. The Lab has been brought in to facilitate the inclusion of Indigenous perspectives, create a two-way learning space and promote opportunities for meaningful economic reconciliation across the value chain as it takes shape.

“It’s beyond just a net-zero system,” Cretney stresses. “It’s about equity and inclusiveness and ensuring future sustainability.”